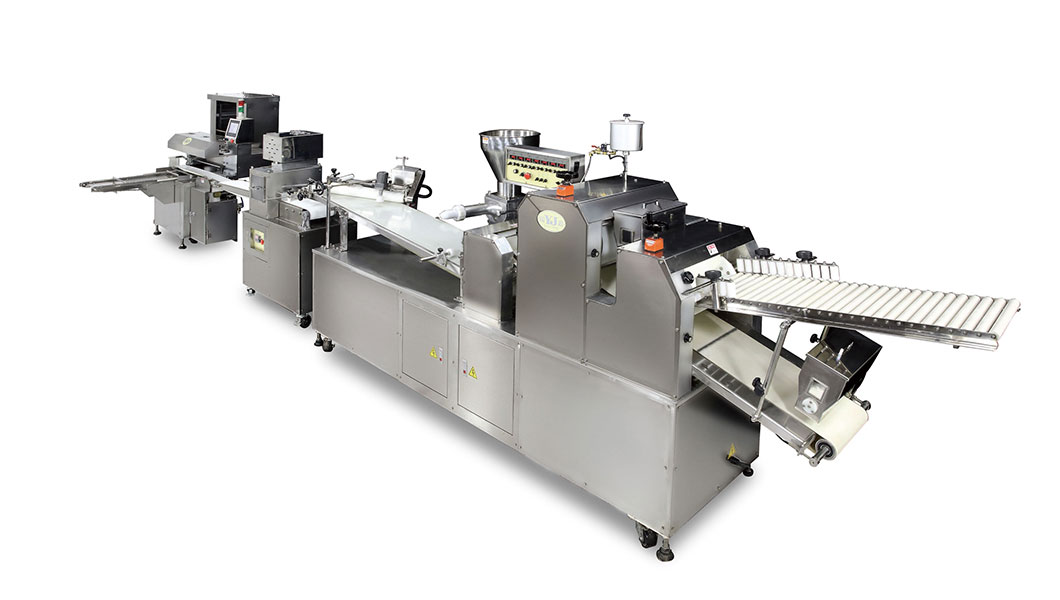

Model number: p-02

Automated Mantou Production Line

- YJ-241 Auto Dough Kneading/Sheeting Machine

- YJ-1510 Dough Forming Machine

- YJ-STB35 Auto-Cutting Machine

- YJ-860 Auto-Arrangement Machine

Considering the diverse needs of manufacturers, we developed a fully automatic mantou production machine that significantly reduces labor costs, enhances production efficiency, and produces delicious mantou with a texture comparable to handmade dough.

In addition to developing high-quality mantou equipment, Yang Jenq also offers comprehensive, customized production line solutions for businesses struggling with equipment planning.

Click the inquiry button below, and our specialists will assist you as soon as possible.

Quantity

Automated Mantou Production Process

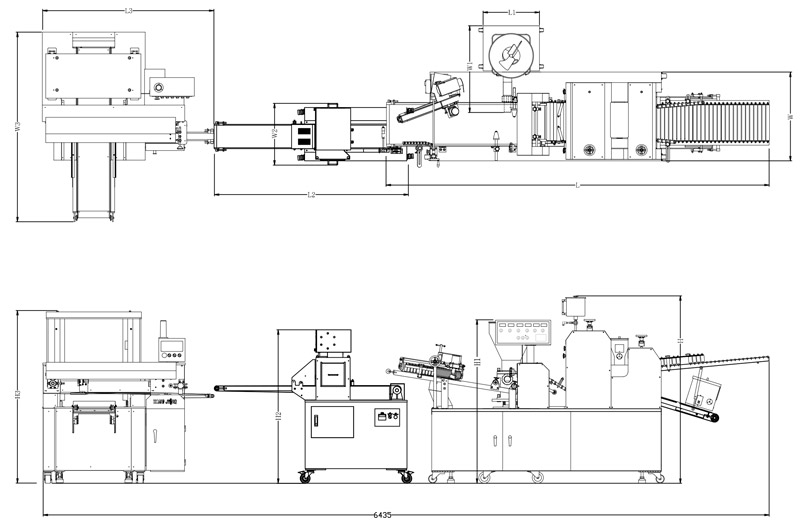

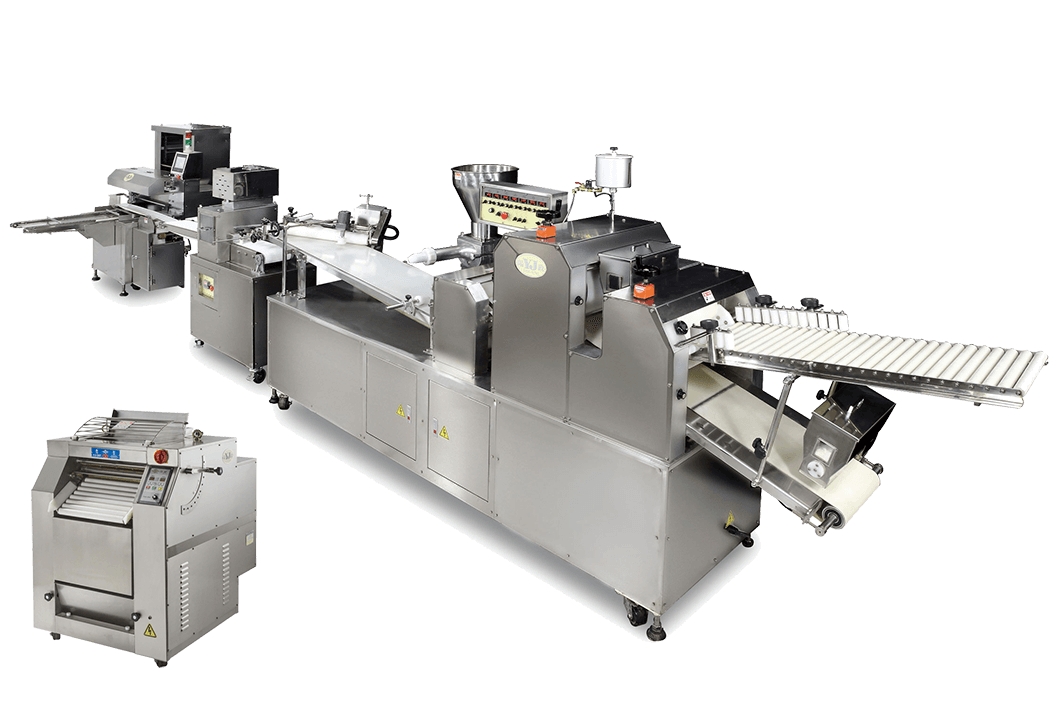

The automated mantou production line from Yang Jenq features a modular design that can be paired with various equipment and attachments, such as a continuous dough sheeter and a multifunctional dough-forming main unit. This allows your production line to become more diverse and flexible. The Yang Jenq automated mantou machine ensures stable product quality and consistent shaping, enabling high-efficiency, large-volume production of mantou.Operating the fully automatic mantou machine is simple. After feeding the dough sheet into the guide rollers, it passes through three adjustable sheeting rollers that gradually thin the dough. The machine then presses it into a standard dough sheet according to the required thickness.

Next, the rolling unit forms the sheet into a long strip, followed by the cutting device that produces mantou in the desired specifications.

This process prevents gluten damage and overheating, preserving the traditional handmade texture and creating mantou that are delightfully chewy and elastic.

Specification

Features

- This machine layers dough in S- overlap multiple times to improve the elasticity and luster of the dough.

- With our user friendly control panel the operator can easily adjust all parameters from this station easily adjusting all equipment such as the conveyor, dough forming speed, filling 1 and 2, kneading, pressing, dusting, cutting and more… The menu guided system is language independent & the large symbols are self-explanatory.

- Large satellite heads with one lower roller treats the dough band particularly gently. In this way the dough sheet stays free of tension and the dough maintains its integrity.

- Our compact, precision AC motor is equipped with an external clutch mechanism. This combination makes it the ideal set up for applications involving frequent START/STOP operations. This allows for higher cutting speeds, increased capacity, and more accurate cuttings lengths.

- Our PLC system has a built in memory and can store up to 99 panning patterns as well as set the arrangement (parallel or cross), reducing manual labor and increasing productivity.

- Capacity: 1,000~12,000 Pcs/per hour

Production Line Combination Introduction

YJ-241 Auto Dough Kneading/Sheeting Machine/YJ-1510 Dough Forming Machine/YJ-STB35 Auto-Cutting Machine/YJ-860 Auto-Arrangement Machine

Contact

Close