Dough Forming

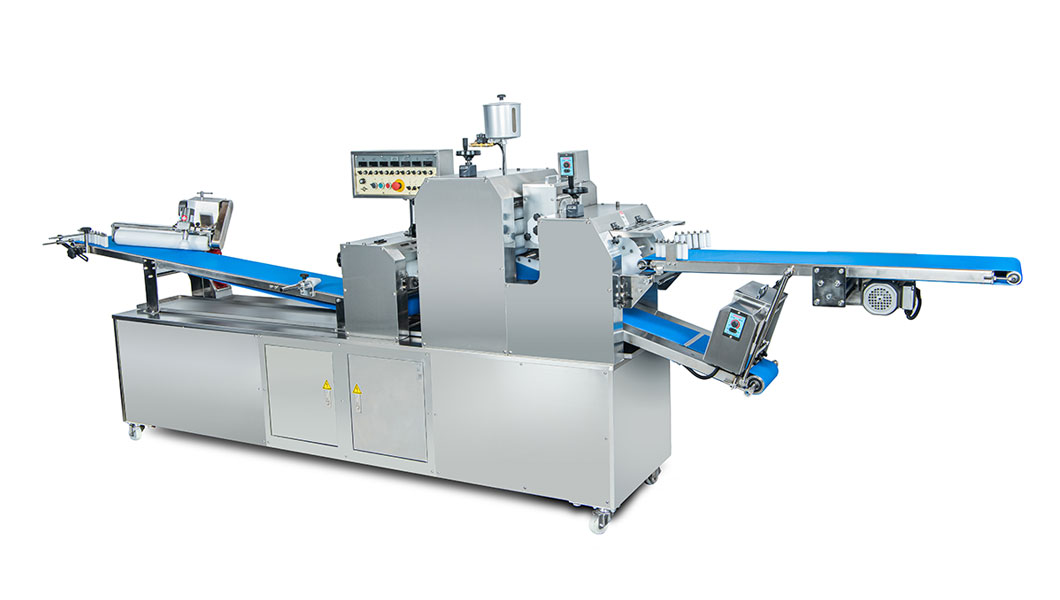

YJ-1910 TANK DOUGH FORMING MACHINE

The YJ-1910 can handle all types of dough and is our most versatile model of dough forming machines. This model is your best choice for Low-Gluten dough commonly used in flaky pastry. Speed, thickness and a variety of other settings can be adjusted allowing for high quality consistent and precise weight tolerances. Different conveyor lengths including custom length are available to support additional filling stations or other processes.

YJ-MCCS DOUGH FORMING MACHINE

The new model-MCCS dough forming machine can independently control the operation speed of the dough belt. The structural design adopts the quick release method to save cleaning time and improve maintenance efficiency: this machine can also be used in multi-station automatic production lines to strengthen the operation of the product process The method has met the needs of taste.

YJ-1520BS DOUGH FORMING MACHINE

All kinds of dough including high water absorbing dough and fermented dough can be produced using this production line. The speed, thickness and other settings can all be adjusted. Additional accessories including an auto cutting machine installed directly on the main unit allows for flexible production of bread in various shapes and sizes.

YJ-1510MD DOUGH FORMING MACHINE

A wide variety of dough types—including high-hydration dough and fermented dough—can be processed on this production line. It is an ideal solution for producing bread and similar bakery products. The speed, thickness, and other settings can all be adjusted. The conveyor length can be customized to accommodate additional equipment, such as cutting units mounted on the main machine, enabling flexible production of breads in various shapes and sizes.

YJ-1510 DOUGH FORMING MACHINE

All kinds of dough including high water absorbing dough and fermented dough can be produced using this production line. The speed, thickness and other settings can all be adjusted. Moreover, the conveyer length can be customized to increase the manual material placement time if necessary, ensuring a consistent quality and a product weight deviation of under 3 grams.