Model number: GaozaiBiscuit

Gaozai Biscuit Production Line

Quantity

Yang Jenq Machinery is a professional manufacturer of Gaozai biscuit production equipment, integrating innovative concepts with patented technology to design automated production lines tailored for large-scale food factories and central kitchens. The Yang Jenq Gaozai Biscuit Machine offers multi-filling capability, customizable stamping, and automatic tray-arranging solutions to meet high-volume production needs. We prioritize every step of the Gaozai biscuit-making process to ensure consistent high quality and reliability. Click below to submit an inquiry, and our specialists will assist you with all questions related to Gaozai biscuit machinery.

Gaozai Biscuit Production Process

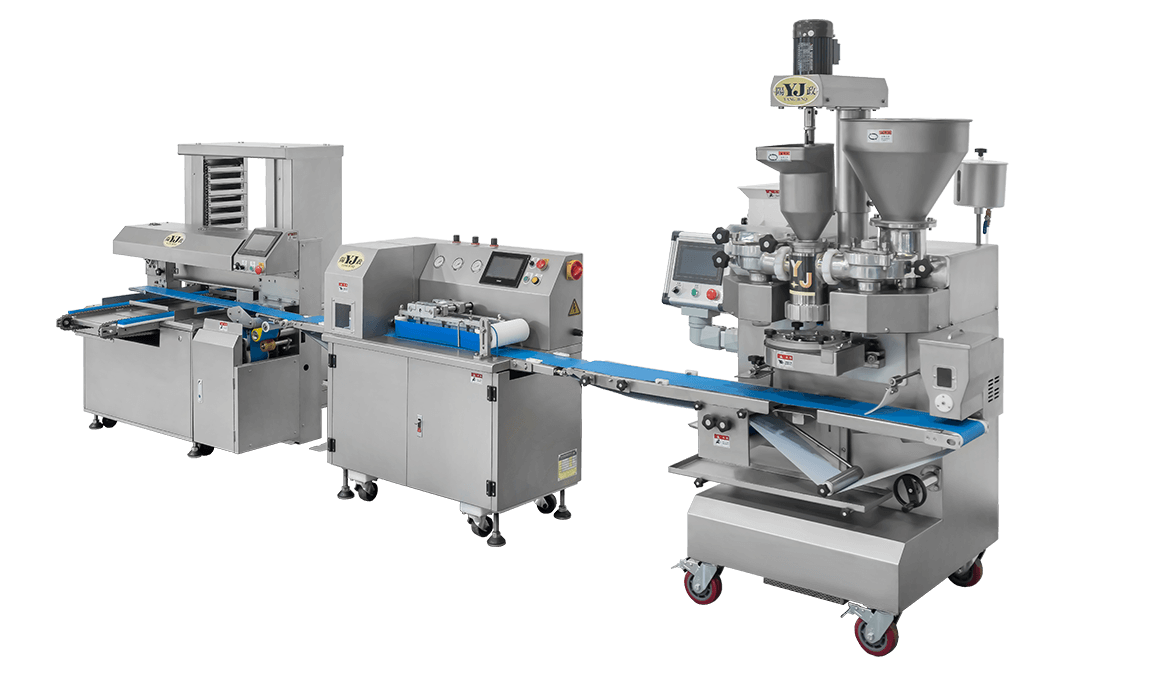

The Yang Jenq Gaozai Biscuit Machine combines a vertical screw and horizontal auger system, enabling two different depositing methods. This design allows precise dosing of dough and filling, forming accurate combined portions. By adjusting the direction of the filling guide, operators can select the most suitable depositing method for various dough types and fillings—including single filling, dual fillings, or layered filling structures—enabling diverse flavor combinations.

The machine can produce biscuits ranging from 15 to 200 grams per piece. The stamping unit can be equipped with telescopic molds, allowing customers to choose from existing patterns or request fully customized designs. Finally, the automatic arranging system places products neatly onto baking trays in either parallel or cross patterns, reducing labor costs, minimizing unnecessary handling, and preventing secondary contamination.

Specification

Features

- A retractable mold or a fixed mold can both be used and our molds all use non-stick plastic material, which is very strong and durable.

- The special bilateral rounding device ensures the evenness of stamping, and two conveyor belts turning at different speeds allows for a 30% increase in forming efficiency and speed.

- A retractable mold or a fixed mold can both be used and our molds all use non-stick plastic material, which is very strong and durable. The precise positioning of mold ejection during blowing ensures the product does not tilt or move, allowing the end product to appear perfect after forming.

- Our PLC system has a built in memory and can store up to 99 panning patterns as well as set the arrangement (parallel or cross), reducing manual labor and increasing productivity.

- Capacity: 1,000~3,600 Pcs/per hour.

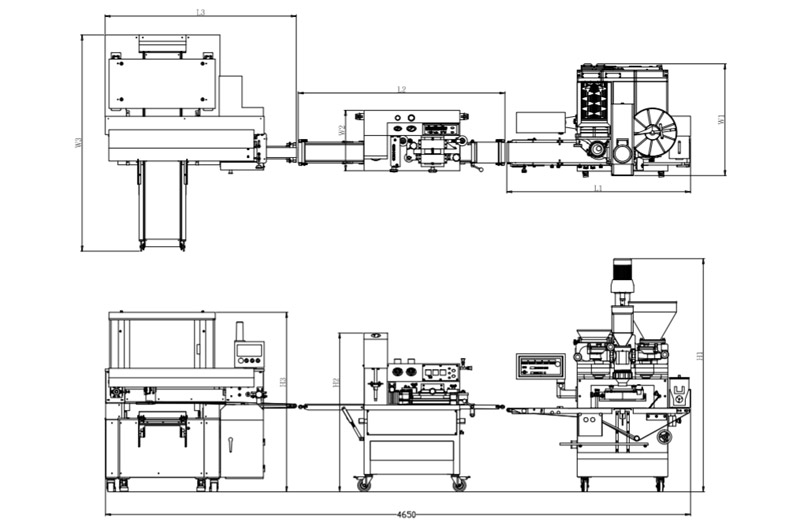

Production Line Combination Introduction

YJ-500 Multi-Function Encrusting Machine/YJ-850C Auto-Stamping Machine/YJ-860 Auto-Arrangement Machine

Contact

Close