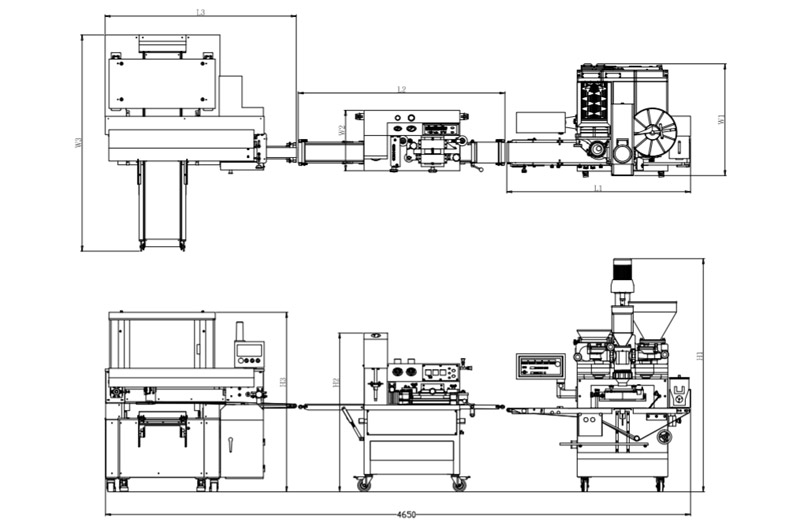

Model number: 08

Taiwanese MeatballProduction Line

Quantity

Meatball (Ba-wan) Production Process Using the Ba-wan Forming Machine

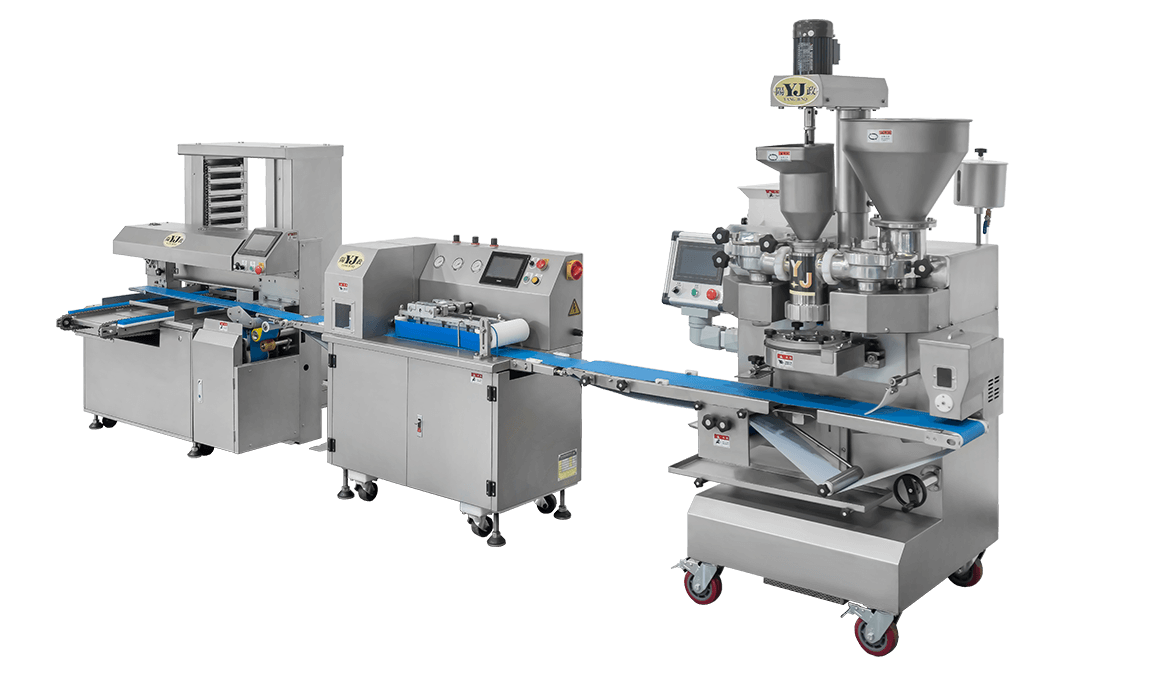

Yang Jenq Machinery’s Ba-wan stuffing and forming machine combines both a vertical screw and a horizontal auger design, enabling two different discharge methods. This allows precise portioning of dough and filling, and by adjusting the direction of the filling guide sleeve, users can choose the most suitable discharge mode depending on the type of dough or filling. This flexibility supports “filling-in-filling” designs, giving the final product diverse flavor variations.The machine can produce Ba-wan weighing from 15 to 200 grams each. The stamping unit can be equipped with telescopic molds, and decorative patterns can be freely selected or customized by Yang Jenq. Paired with an automatic tray-aligning system, the machine arranges products onto baking trays in either parallel or cross patterns. This automated process reduces labor costs, minimizes unnecessary handling, and effectively prevents secondary contamination.

Specification

Features

- A retractable mold or a fixed mold can both be used and our molds all use non-stick plastic material, which is very strong and durable.

- The special bilateral rounding device ensures the evenness of stamping, and two conveyor belts turning at different speeds allows for a 30% increase in forming efficiency and speed.

- A retractable mold or a fixed mold can both be used and our molds all use non-stick plastic material, which is very strong and durable. The precise positioning of mold ejection during blowing ensures the product does not tilt or move, allowing the end product to appear perfect after forming.

- Our PLC system has a built in memory and can store up to 99 panning patterns as well as set the arrangement (parallel or cross), reducing manual labor and increasing productivity.

- Capacity: 1,000~3,600 Pcs/per hour.

Production Line Combination Introduction

YJ-900T Multi-Function Encrusting Machine/YJ-850C Auto-Stamping Machine/YJ-860 Auto-Arrangement Machine

Contact

Close