Model number: TaroPasteBun

Taro Paste Bun Production Line

Quantity

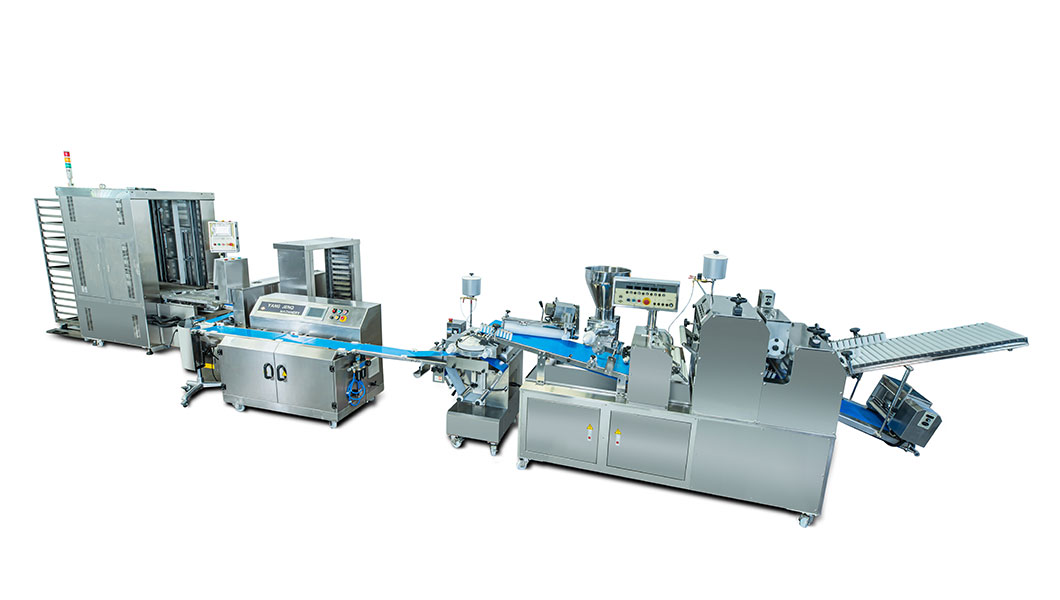

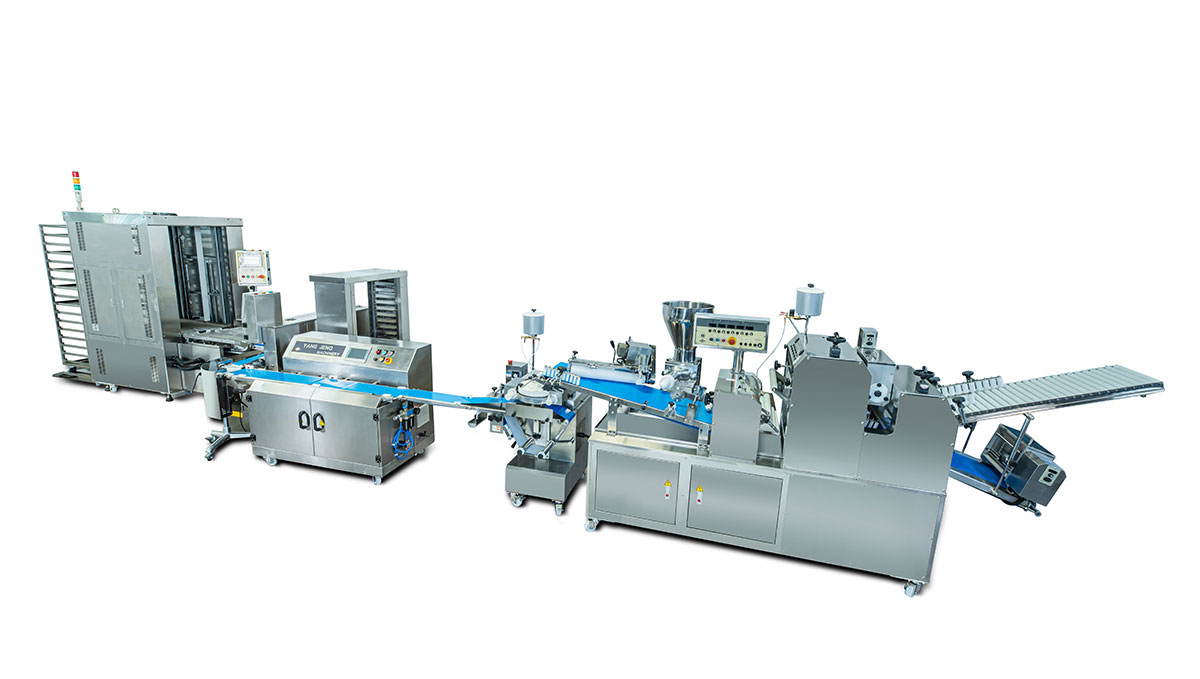

With years of research, development, and testing in food machinery, Yang Jenq has developed a highly efficient, precise, and versatile automated Taro Bun production machine. The fully automated Taro Bun machine eliminates labor-intensive manual steps such as dough rolling, filling, and pleating, significantly reducing labor and production time. Requiring only two operators, it ensures stable quality and high-efficiency production to meet large-scale Taro Bun demand. Click below to submit an inquiry and upgrade your Taro Bun production line with superior automation.

Taro Bun Production Process

Yang Jenq’s automated Taro Bun machine is ideal for medium-to-large Chinese pastry factories and central kitchens, enabling stable and rapid production. The automated production line supports the expansion of additional auxiliary equipment and can be configured with different machines depending on production requirements. Line speed, dough-sheet thickness, and other operating settings can be adjusted simultaneously, ensuring both flexibility and efficiency while maintaining excellent product quality and texture.

The automatic Taro Bun machine uses high-speed, rhythmic dough beating to create a dough texture with enhanced elasticity and layered structure. It can automatically wrap various types of pre-made fillings—including taro paste, red bean paste, and mixed nut fillings—into the dough. The smooth, chewy dough combined with diverse fillings delivers the rich aroma and delicious flavor of traditional Taro Buns with every bite.

Specification

Features

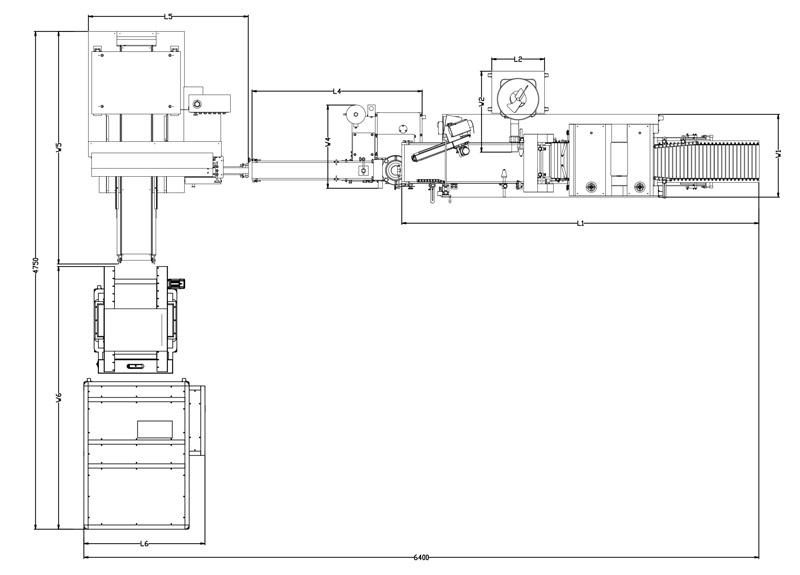

- This machine layers dough in S- overlap multiple times to improve the elasticity and luster of the dough.

- With our user friendly control panel the operator can easily adjust all parameters from this station easily adjusting all equipment such as the conveyor, dough forming speed, filling 1 and 2, kneading, pressing, dusting, cutting and more… The menu guided system is language independent & the large symbols are self-explanatory.

- Large satellite heads with one lower roller treats the dough band particularly gently. In this way the dough sheet stays free of tension and the dough maintains its integrity.

- The optical sensors provide automatic stop/start of dough path to prevent collisions between the different dough stations.

- With a 16 L hopper capacity this machine is capable of large volume deposits of meat, bean, Jam, grain filling and more. Our industrial size filling depositor can be connected to the main production line system meaning the deposit speed and rate can be accurately adjusted through the main control panel allowing for fully automatic production.

- Our knife systems are made of specific industrial food grade resin from Japan suitable to the most stringent hygiene requirements .4 hand knob bolts secure the mechanism allowing easy change and cleaning.

- Our PLC system has a built in memory and can store up to 99 panning patterns as well as set the arrangement (parallel or cross), reducing manual labor and increasing productivity.

- The Conveyer Belt Mechanism can arrange two trays at the same time, which accelerates product arranging time, thereby increasing productivity.

- Capacity: 1,000~7,200 Pcs/per hour (Lifting up capacity 3600 pcs/per hour)

Contact

Close